Predictive Operations

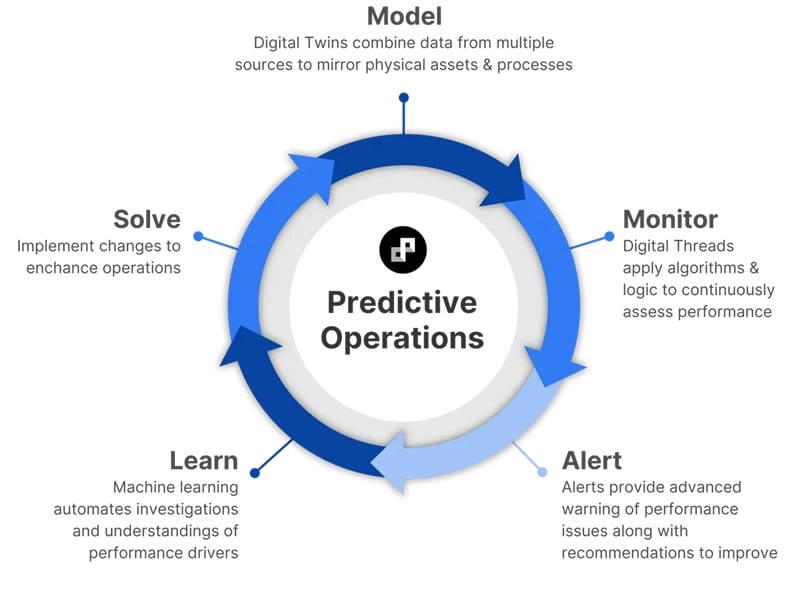

A Predictive Operations Platform is a SaaS-based system for industrial IoT (factory and equipment) that takes your organization from reactive to proactive operations.

Imagine if you weren’t reacting to unexpected issues or having to deal with the fallout of unnecessary downtime or product waste. Preventing these issues from occurring in the first place will ensure your engineers devote more time toward innovation and less time toward fighting fires.

With the advent of predictive operations, you no longer need to live on the edge - constantly concerned about what’s around the next corner and whether your process will be effective enough to prevent a catastrophic outcome.

TwinThread’s Predictive Operations Platform reimagines continuous improvement with the latest digital technologies and AI - enabling the next frontier in automation that you can apply more consistently and much faster than previous automation technologies.

TwinThread Empowers the Operationalization of Opportunities for Colgate-Palmolive

"Looking at the broader view of the opportunity - it could be from a financial... or efficiencies [perspective] - ... energy efficiencies, labor efficiencies, diverting resources to different areas that you may not have [thought of] before..."

— Warren Pruitt VP Global Engineering Services, Colgate-Palmolive

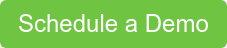

Simply put, we start by transforming your industrial data into predictive models. Automating this step means your engineers don’t have to waste time finding and curating data.

From there, we give you the ability to operationalize those models and automate performance monitoring - meaning our system of algorithms will watch over your processes with an expert eye 24x7x365 (whether a human is watching or not).

Imagine if you received alerts before something bad happened versus after something bad happened. We offer advanced warning alerts paired with recommendations for resolution, so you can prevent issues from ever occurring instead of reacting to them as they are happening.

Keeping with the theme of automation - our predictive operations platform produces an analysis of your process automatically - extracting deep insights that would not be practical to extract through manual analysis. This, again, saves your experts time and empowers them to learn much faster than previously possible. The ultimate goal of a predictive operations solution is to give your teams the tools they need to optimize your processes and equipment 10x faster.

Now that you know what Predictive Operations is, who benefits from using it?

Based on TwinThread’s 30 years of experience, we’ve tailored our product to address the needs of these important roles:

- Executives: predictive operations provide the analytics and digital transformation strategy that delivers return on investment quickly.

- Managers: our predictive solutions offer a Continuous Improvement process right out of the box that is highly digitized and fast to implement.

- Engineers: TwinThread offers up automated tools that unlock the insights most likely to deliver ROI - freeing engineers to focus their time and effort on solving interesting problems versus finding data.

- Data Scientists: our predictive operations platform establishes an analytics strategy that automates data gathering, cleansing, and context - allowing teams to focus on solutions.

- Frontline Workers: as with other industrial IoT systems, a predictive operations platform provides recommendations that empower every operator to be the best operator.

No matter the role, a predictive operations platform provides the tools needed to take the performance of your organization to the next level.

TwinThread’s customers typically enjoy 10X ROI on their subscription investment - that means 30-60 day paybacks.

Our predictive operations platform comes standard with pre-built predictive applications that automate every aspect of model development and operationalization.

These applications work out of the box, not only to deliver insights but to drive proactive action in real-time. Some of the key use cases, and the metrics they solve for, are:

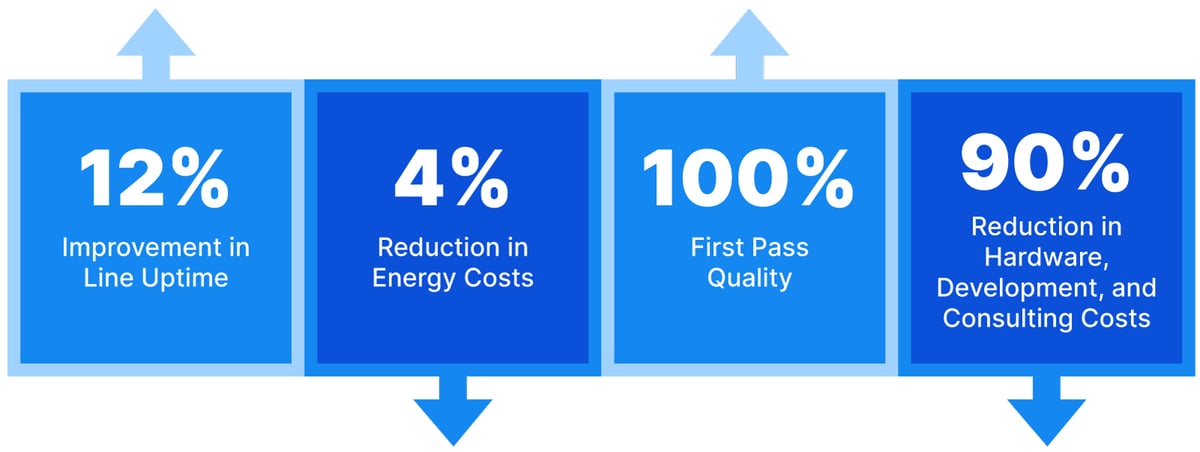

- Predictive Quality: Solving quality issues before they occur. For example, you could achieve 100% First Pass Quality by predicting outside optimal conditions during production - ensuring you prevent outside specification products and unnecessary waste.

- Predictive Uptime: Advanced warning of downtime causes - allowing you to increase Uptime 10-12%. This will allow you to accurately forecast the Probability of Downtime. So, instead of diagnosing why you went down, you can prevent your equipment from going down in the first place.

- Predictive Throughput: Proactive, real-time recommendations to maximize production. Your Production Rate can be continuously improved as this application constantly uncovers opportunities for optimization within your process.

- Predictive Energy Efficiency: Insights that allow you to operate within your energy consumption sweet spot, 24x7x365. If lowering Energy Cost / Unit is your goal, this predictive application delivers everything you need to decrease your energy footprint by 5%.

- Predictive Asset Reliability: Leapfrog condition-based maintenance strategies with a predictive maintenance strategy that can be implemented in hours. Doing this will reduce maintenance costs by 5-10%.

- Predictive Asset Life: Pre-built application that gives you everything you need to maximize the life of your equipment, using data. This will allow you to increase life by up to 20%.

Regardless of the application you focus on first, your Predictive Operations Platform will establish a proactive operations strategy that can be easily expanded as new problems and applications arise.

With more innovation and proactive action built into your operating strategy, it stands to reason that you’ll experience the same high return on investment that others have. And, the kicker is that this value resides in your current data - just waiting to be exploited - without the need for capital investment or large investments in development.

TwinThread offers multiple implementation options, from completely self-provisioned to full turnkey.

As part of our base subscription, we offer a host of onboarding resources including online support, regularly scheduled Onboarding Accelerator webinars, and no-agenda office hours where you can interact live with TwinThread's Customer Success Consultants.

These resources are provided to accelerate your adoption and ensure your self-sufficiency in managing the platform. The most popular implementation option is our "assisted" onboarding, where TwinThread engineers (or our partner engineers) work directly with your team to implement the first use case on the first process / asset to support you in achieving self-sufficiency within the first implementation phase.

If you feel you don't have the necessary resources for either of the implementation approaches mentioned above, TwinThread (and its partners) can offer turnkey onboarding as well as a fully managed service deployment.

The first key step is to identify a problem worth solving. Pick a metric that has

clear room for improvement and will really move the needle for your business.

Next, work with the TwinThread team to identify the solution that optimizes that metric, and execute a production pilot on a limited number of assets / lines to prove the impact on that metric. Then, use the success of the production pilot to justify and fund a roll-out.

Provided you follow our Onboarding Accelerator process, we make it very easy and low risk for you to execute a production pilot and build your justification for roll-out in as little as 30 days.

You’ve built up decades of automation system data - but what are you doing with it?

There are huge opportunities for proactive improvement of your operations, just waiting within your data to be put to good use. Uncovering and operationalizing these insights will give you the return on your data you’re looking for.

Our predictive operations platform gives your engineers and frontline workers the power to become proactive versus reactive - meaning they can prevent issues before they happen. The pre-built, metric-specific applications that come out of the box with our predictive operations platform allow your experts to attack your problem areas quickly and directly. These tools give you a modern Continuous Improvement process that results in better performance and significant cost savings.

And once you have your modern Continuous Improvement process in place, it also means you have created a highly curated set of data about your process and your equipment that can be transformational when incorporated into a broader Enterprise Analytics strategy.

With TwinThread’s Operations Data Lake, you can have a quick start with critical mass that will propel your Enterprise Analytics Strategy and deliver even greater returns on your data.

We aim to provide you with speed to value and eliminate the development risks typically associated with implementing AI and advanced analytics technology.

Imagine if you didn’t have to spend 80% of your Enterprise Analytics budget wrangling, curating, and securing operations data. This would free your organization from the unnecessary investment of time, liberate your experts from monotonous tasks, and free up a lot more space for innovation. Shouldn’t that be how you look at your data - as a gold mine of opportunity to further innovation - as opposed to a burden to manage and secure?