TwinThread Seminar Series: Achieving Your Manufacturing Goals in the Age of Uncertainty

Using an AI-Assisted Top-Down / Bottom-Up Process to Accelerate Innovation & Operationalize Results

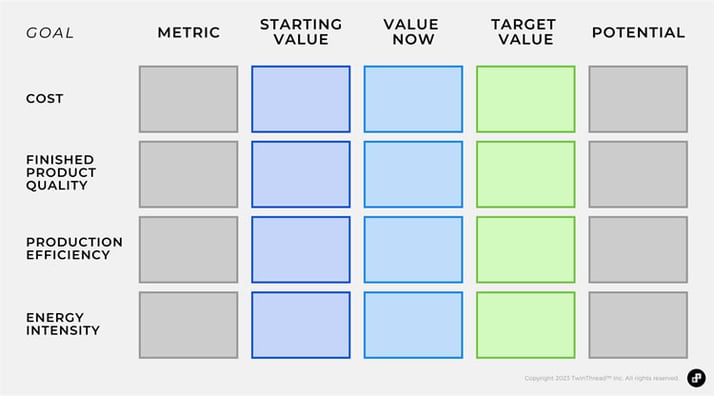

We all have them - scorecards and goals.

We all have operating plans to achieve them.

We all have technology and process backing them up.

And yet… Does this sound familiar to you?

- Are you worried about the high cost of materials?

- Have you been given an energy mandate and are uncertain of your order of solve?

- Does operating performance vary by SKU, line, plant or region?

- Do you know why?

- Are you able to pivot quickly in the face of supply chain disruptions?

Starting with a top down approach to select optimum targets, and then implementing a bottoms up approach to hit those targets is common.

However, manufacturing being what it is, you may have run into some hurdles:

Insufficient Data: Data in multiple, unrelated units, not enough data, bad or missing data

Time Constraints: Not enough time to dig into and analyze your data

Human Subjectivity: Meaning it’s hard for someone to analyze a problem objectively when it could mean big changes for them

Change Adoption: Having the ability to confirm that a change, once implemented, continues.

Over the next few weeks, I’ll be breaking down the steps of an AI-assisted, top-down approach to optimizing manufacturing performance.

Topics:

The Basics

- What are the elements of an AI Assisted Top Down Approach?

- What is a bottoms up approach and when should it be used?

- The truth about KPIs

- Top Potential V Top Cause

Technology Assists:

- Data Lakes

- Digital Twins and Threads

- Reporting Engines V Analytics

- AI

Making it Stick

- Execution Execution Execution

- Iteration and Innovation

- Examples

- Quality

- Production

- Energy Intensity

- Managing Change

Tags:

Blog, Digital Twin, Quality, Digital Thread, IIoT, AI, Contextualization, Visualization, Operationalize, Efficiency, KPIs, Manufacturing, Operational Metrics, Innovation, Energy Cost Reduction, Operational Costs

June 28, 2023

Sheila’s management philosophy produces results. By enforcing “just the right” amount of infrastructure, she enables teams to work towards the ultimate, shared goal of the highest quality customer experience.

She’s a proud graduate of Boston College (Business and Computer Science) and Babson (MBA 2019), a native New Yorker, and a fierce advocate for women in tech.