Industrial AI

Platform

Purpose-built by operations experts for operations teams, TwinThread’s Industrial AI delivers actionable intelligence that helps your teams run operations more efficiently, with less downtime and better results at scale.

AI is a Cluttered Landscape

Every industrial company faces the same challenges: experienced frontline workers are departing, producing and organizing high-quality data remains a struggle, and security is a constant concern. Industrial AI holds real promise to solve some of these issues, but most pilots stall, buried under technical debt, complex integrations, and unclear paths to scale.

TwinThread is the exception.

Our Industrial AI is one pillar of a complete platform built to work with the people and systems you already rely on, and showcase measurable value from day one.

Solutions for Assets & Processes

Pre-built models address challenges like uptime, energy, and quality optimization and remove months of development.

Closed-Loop Recommendations

AI doesn’t just alert you; it acts. It detects anomalies, recommends fixes, and can even implement them autonomously.

Immediate Value

Connect data in minutes, deploy solutions in hours, and see results within days.

Clear Path to Scale

Begin with a single use case and expand it seamlessly across lines, plants, and your entire global enterprise, leveraging an architecture proven to scale in months.

Success Story: AI that Scales

Global provider of data center design, construction, and operation services implements Virtual Operations Center

TwinThread manages over 650,000 assets across 450 sites for a single customer

A Complete Industrial AI Platform

TwinThread unifies multiple layers of intelligence that continuously learn, guide, and optimize, making operations simpler, more stable, and more productive.

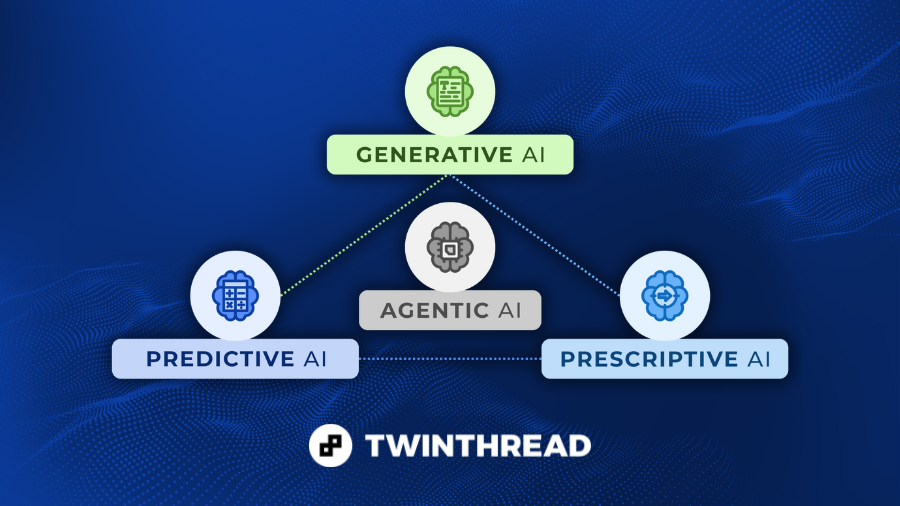

Predictive AI

Anticipates anomalies and offers solutions.

Generative AI

Explains issues and guides you to a solution.

Prescriptive AI

Recommends the next best course of action.

Agentic AI

The layer connecting it all - closing the loop behind the scenes.

Fuel Industrial AI With Your Data

Industrial AI requires quality data, and TwinThread's agents can connect to almost any legacy industrial data source in minutes. TwinThread’s Platform then collects, contextualizes, and standardizes data from historians, PLCs, MES, and more to form a structured, reliable foundation.

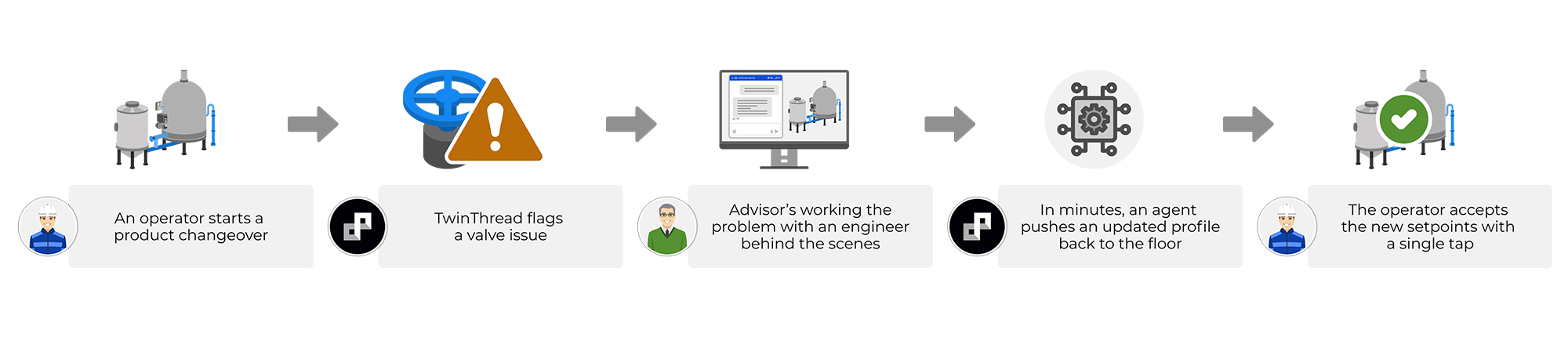

Embed AI in Every Process

TwinThread's Industrial AI turns every workflow into an intelligent, self-diagnosing, correcting, and improving system.

In routine plant activities like a product changeover, AI can flag anomalies instantly. Engineers can work with TwinThread’s Generative AI to diagnose the cause and use Prescriptive AI and agents to push recommended setpoints back to operators.

With teams that are powered by every facet of Industrial AI, decisions happen on a new timescale: minutes and seconds.

Empower Every Role

Improve the day-to-day of every role on your team.

Operators

Make better decisions and respond with the right action at the right time.

Engineers

Improve, innovate, and problem-solve faster.

Digital Teams

Remove data wrangling from the picture and focus on more meaningful innovation.

Real Results from Real Plants

Grow revenue and see immediate ROI through an Industrial AI Platform trusted by industrial leaders around the globe.

Toray

Manufacturer of engineered plastic films applies Digital Twins and Industrial AI to improve line stability and uptime

Hill's Pet Nutrition

Global manufacturer of premium pet nutrition products applies Digital Twins and Industrial AI to drive quality to new heights

Resideo

Global provider of smart home products and systems launches new digital service for residential utility optimization

Want to learn more about TwinThread?

Connect with Sales

Build a business plan to deploy and scale Industrial AI in your organization.

Talk to an AI Consultant

Solve your organization’s productivity challenges with Industrial AI.