Fast Learners, Smart Equipment

Forward-thinking companies hypothesized they could find a predictive analytics partner that could process their data in real-time.

Vision

Differentiate from the competitors.

Solution

Use TwinThread predictive analytics to extend equipment life, rapidly identify operational inefficiencies, centralize operations.

Results

A proactive full life cycle asset management solution extended fleet life, improved fleet uptime and reduced maintenance costs driving competitive advantage.

Stats

- Double digit asset life improvement

- Double digit reduction in repair costs

Background

Machinery manufacturers operate in a highly competitive market where the ability to offer incremental or substantial advantages to customers is critical. Some manufacturers have explored using Industry 4.0 technologies stand-alone with limited success. Others have considered a more integrated model.

A Visionary Approach

Heavy equipment manufacturing is one of the largest and most competitive sectors of the manufacturing economy and includes items such as construction machinery, engine equipment, industrial process controls, agricultural equipment, and turbines and turbine generators.

The primary world market for heavy equipment is enormous - estimated at $200 billion dollars plus in oil and gas alone. There is also a thriving secondary market around equipment maintenance where third parties provide extended support contracts around preventative maintenance, repair and replace services.

The Challenge

Markets served by heavy equipment manufacturers face substantial economic pressures from tariffs, declining oil prices, and budgetary pressures. With individual asset values of $500,000+, companies in this industry can substantially impact capital and operational financials by improving machine performance. Equipment manufacturers, service providers and operators are exploring technology to improve overall equipment operation, and to reduce maintenance costs, specifically around extending life, and in enhancing fleet and personnel performance.

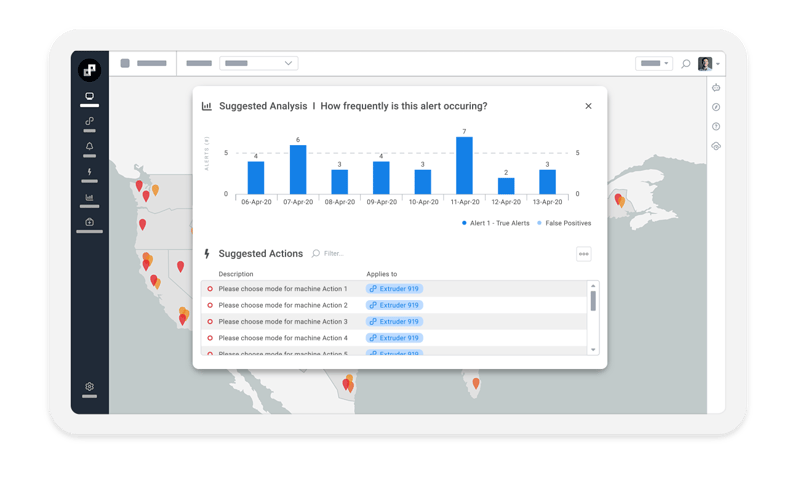

The most optimum solution would deliver alerts and recommendations in real time to local crews and operating centers, however the massive amount of data involved can stymie many asset management platforms, forcing reactive rather than proactive service models.

Forward-thinking companies hypothesized they could find a predictive analytics partner that could process their data in real-time despite its scale, allowing them to optimize their predictions, deliver alerts in real-time and integrate them with their existing operations centers, creating a next generation proactive asset operating center.

The Solution

These innovators are teaming with TwinThread, using TwinThread’s Predictive Operations Center to use all of their data to deliver real time monitoring and predictive analytics on machine performance including utilization, crew dispatch, replacement cycles, maintenance activities improving and/or extending performance, and identifying underlying root causes for component failure. They are integrating this new capability with their veteran field services and operations centers to create cutting edge proactive asset management capabilities.

The Result

In a matter of weeks performance improvements were realized and then quickly scaled to cover all equipment in each company’s fleet - improving overall fleet efficiency, saving millions of dollars annually and ultimately leading to lower cost of production for equipment operators.

The teaming of operating experience with cutting edge technology offers competitive advantages to manufacturers and service providers including the ability to learn and react more quickly competitively price, offer additional services around preventative maintenance plus cost sharing services models - raising these innovators above their peers.

Lastly, by investing in a platform rather than a point solution these same customers are moving on to address other asset challenges including predictive quality and overall asset efficiency with little incremental technology investment.