Process Manufacturers

A Platform For

Manufacturers are facing a perfect storm of productivity challenges due to aging infrastructure, accelerating skills gaps, volatile supply chains, and regulatory compliance burdens.

With TwinThread, you can create a Virtual Operations Center that harnesses the power of Industrial AI and Digital Twins to increase productivity, reduce downtime, and improve energy efficiency at a single site or across your global operations.

We serve a broad range of Process

and Hybrid industries

TwinThread specializes in complex process and multiple-mode manufacturing where quality, efficiency, and sustainability are paramount.

Consumer Products

Food & Beverage

Plastics

Packaging

Pulp & Paper

Materials

Specialty Chemicals

Metals & Mining

Oil & Gas

We empower you to deliver results

Embrace and extend the automation you have today by adding Industrial AI. Attack common productivity challenges out of the box and enable faster, more automated decision-making at all levels of the organization.

Enable autonomous operations

There are multiple steps in the journey towards the autonomous plant. Get started quickly and easily with pre-built solutions that deliver value at each step.

Deliver next-level efficiency

Tracking metrics is one thing. Driving improvements around those metrics in a repeatable way is another. TwinThread gives you the tools and capabilities to modernize your Continuous Improvement process with Digital Twins and Industrial AI.

Turbo-charge your legacy MES

Add uptime, throughput, and quality optimization directly on top of your MES. Don’t stop at tracking performance; add Industrial AI to evolve into a self-optimizing plant.

Don't have an MES yet?

Deploy MES “Lite” first using TwinThread. Use Digital Twins and Industrial AI to go beyond just measuring OEE and optimize every component with autonomous recommendations.

Make every operator your best operator and every run your best run

No more “little black books” kept by your most experienced operators. Fully digitize recipes, centerlines, and operating practices. Apply Industrial AI to continuously optimize so everyone delivers consistent results.

Profit from all the data in your historian

The more you use your historian data, the more you wish you could do even more. Integrating TwinThread with your historian means you can apply cutting-edge, automated analytics across all your data. All you need to bring is your process expertise; we’ll automate the rest.

Optimize batching like never before

Take the “golden batch” concept to the next level with Industrial AI. Optimize yield, quality, cycle time, and phase-level control with a level of fidelity and automation never before possible.

Extend your Quality Management System to create a modern Quality Optimization System

There’s no need to replace your legacy Quality Management System. Integrate TwinThread to add Industrial AI capabilities that create a clear path to autonomous control of multiple quality objectives.

Deploy an “open and scalable” predictive maintenance strategy

Too many alternatives lock you into vendor-specific sensors and data ownership conflicts. Apply TwinThread on top of your existing data and multiple vendors’ sensors. Effortlessly combine asset, process, and vibration data with scalable Industrial AI to create a complete picture of asset health and stay ahead of failure modes.

Attack all elements of energy intensity

Optimize all plant utilities across Water, Air, Gas, Electricity, and Steam. Apply Industrial AI across energy sources, energy consumers, and energy converters within the plant to create a complete picture of Energy Intensity. Easily integrate that data with your enterprise sustainability efforts.

Enable an open Industrial Data Fabric

We open up proprietary edge and cloud data sources and integrate them seamlessly with your preferred open Industrial Data Fabric. Use TwinThread to optimize cloud costs by intelligently optimizing Gold, Silver, and Bronze consumption.

Leverage process expertise across your enterprise

Create, automate, and scale monitoring rules and actions for a single plant or for hundreds of plants simultaneously. Apply your domain expertise efficiently to maximize value across the enterprise.

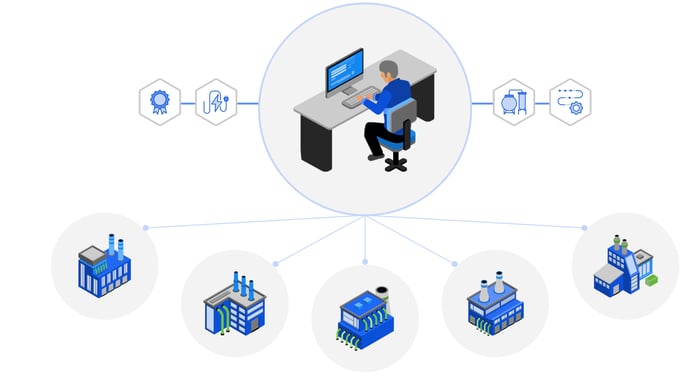

Implement a Virtual Operations Center to scale benefits further

Manage improvement initiatives, cases, alerts, and monitoring at scale using TwinThread’s Virtual Operations Center.

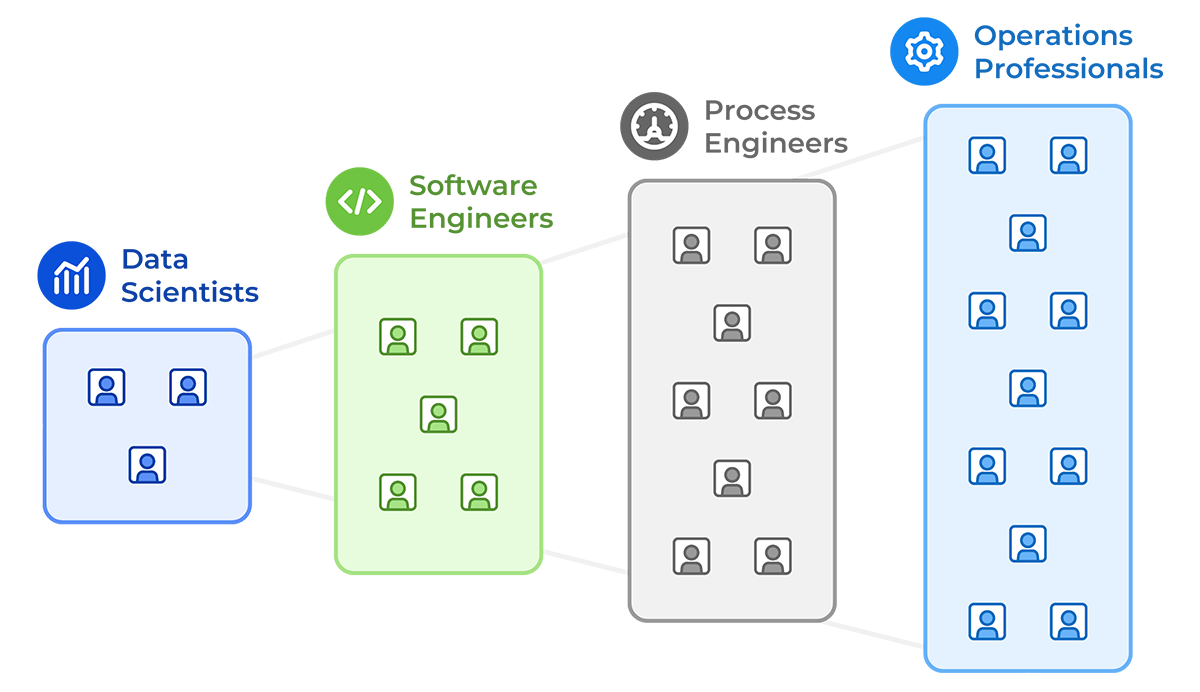

We understand how to scale

Over 30 years of experience in industrial automation and a track record of delivering some of the most highly-scaled IoT and Analytics solutions in the world have taught us what it takes to fully realize the benefits of Industrial AI.

Real Solutions. Real Scale. Real Results.

Expand your innovators

Using TwinThread, you don’t need to be a software developer or data scientist to apply Industrial AI. Extend the reach of your process and operations experts with AI assisted research, diagnosis, and improvement recommendations.

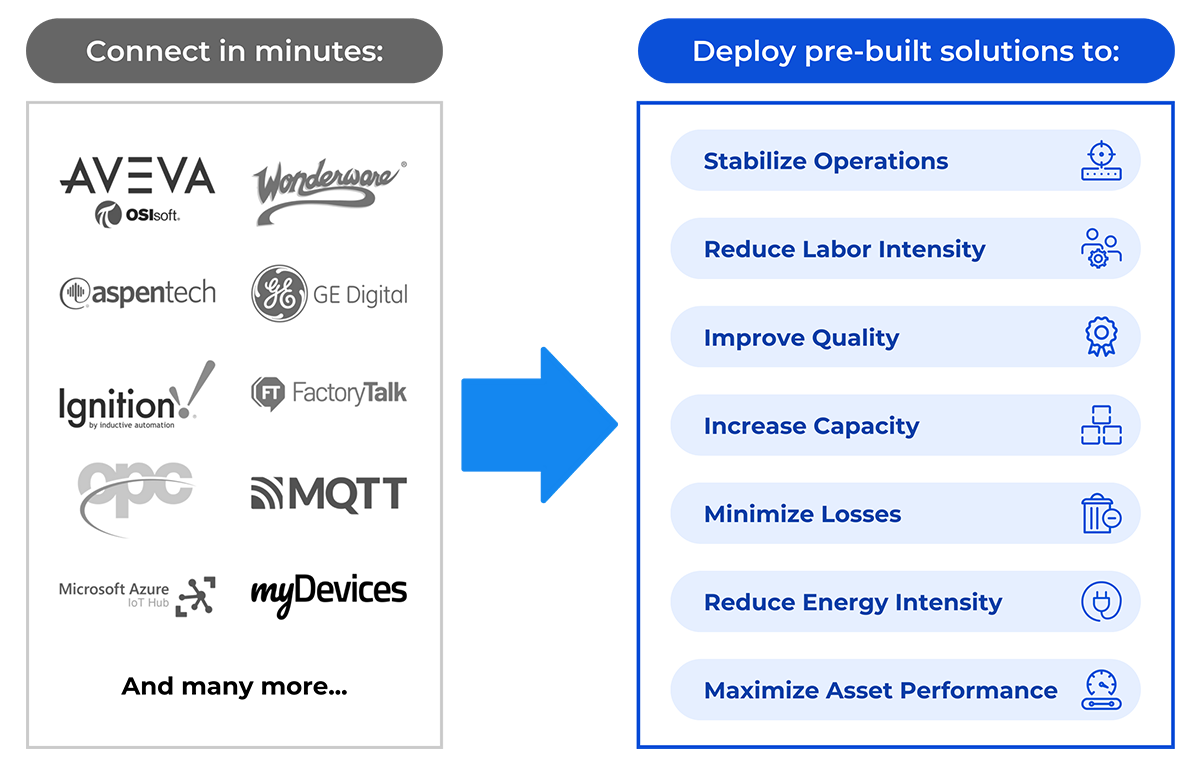

Connect in Minutes to:

- AVEVA (OSIsoft)

- aspentech

- Wonderware by AVEVA

- GE Digital

- Ignition!

- FactoryTalk

- OPC

- MQTT

- Microsoft Azure IoT Hub

- myDevices

- and many others...

Deploy pre-built solutions to:

- Stabilize Operations

- Reduce Labor Intensity

- Improve Quality

- Increase Capacity

- Minimize Losses

- Reduce Energy Intensity

- Maximize Asset Performance

Put the data you already have to work for you

More data is always better, but why not get the most from what you have today?

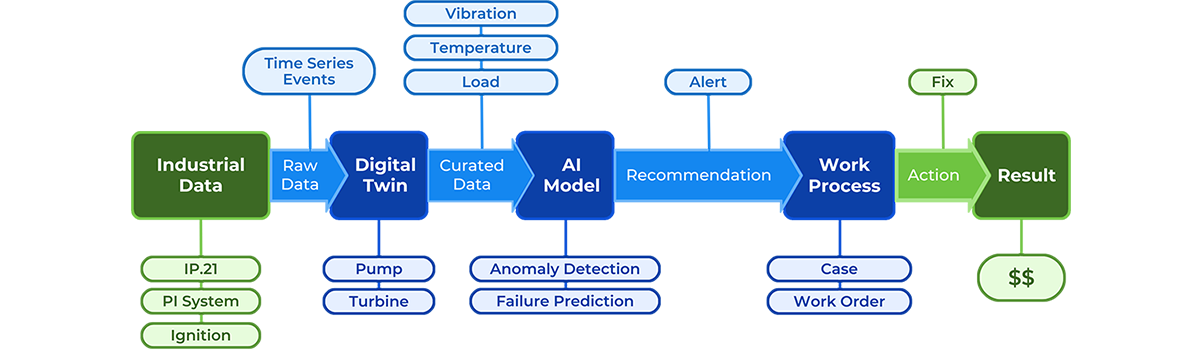

Go beyond insights

Insights without action are worthless. TwinThread gives you everything you need to fully operationalize Industrial AI in your organization. Move from raw data to action on a single production line or across all plants in your enterprise with ease.

What is “operationalization"?

The process of turning insights into action.

Where is operationalization needed?

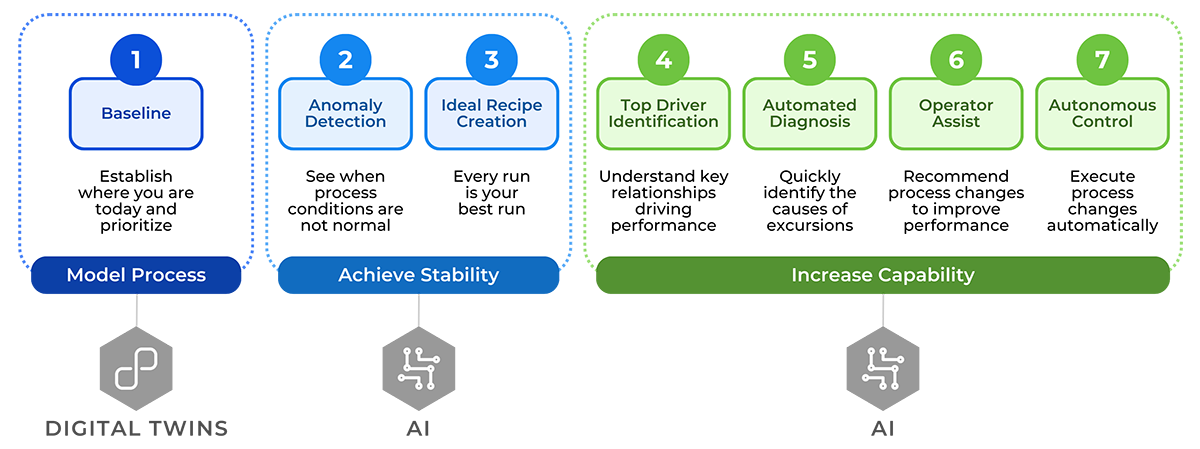

Build your path to autonomous operations

Much like the autonomous driving space, there are multiple levels of autonomous operations. Each step provides significant value, so even if your goal isn’t full autonomous control in the near future, starting this journey today has many benefits.

We revolutionize continuous improvement

CI teams can model, monitor, and optimize much faster and with higher impact using the power of Digital Twins and Industrial AI together. Digital Twins provide the framework to standardize and scale, while Industrial AI provides the capabilities to work smarter and drive automation to new levels.

AI-Enabled Continuous Improvement

- Model:

- Compare

- Rank

- Benchmark

- Monitor:

- Learn

- Diagnose

- Stabilize

- Optimize:

- Predict

- Recommend

- Prevent

Create your Virtual Operations Center

Extend the reach of your experts to deploy and manage improvement initiatives across multiple sites simultaneously.

Stay Connected with Industrial AI Trends and Platform Features

Get quarterly updates from our experts. Stay ahead with insights and strategies for digital transformation and operational excellence.