Perfect Quality

Innovate using your data, your team, and the power of AI-based digital twins to improve first pass quality, and reduce waste and rework like never before.

Optimize Quality, Help Your People

Try to imagine predicting the weather without knowing the time of year, or where you were. That's been the fallacy of Quality systems forever. You will never achieve your Quality standards when you can't use all of your data in context.

With TwinThread you can. Whether your quality systems are on or offline, your raw material data comes from outside of your plant, or your energy data is in random units of measure, TwinThread takes it all and creates the first holistic model of all the factors that create quality product, and those that don't - And then alerts you to those factors with sufficient time for you to action them.

When you're ready, TwinThread addresses those factors for you, so your people can focus on what only they can do.

How Colgate-Palmolive Achieved Autonomous Quality

"The goal was to convert out of the black book and into prescribed startup conditions based on the algorithms within the Digital Twin."

— Darren Haverkamp Technical Director, Colgate

Moving from Reactive to Autonomous Operations

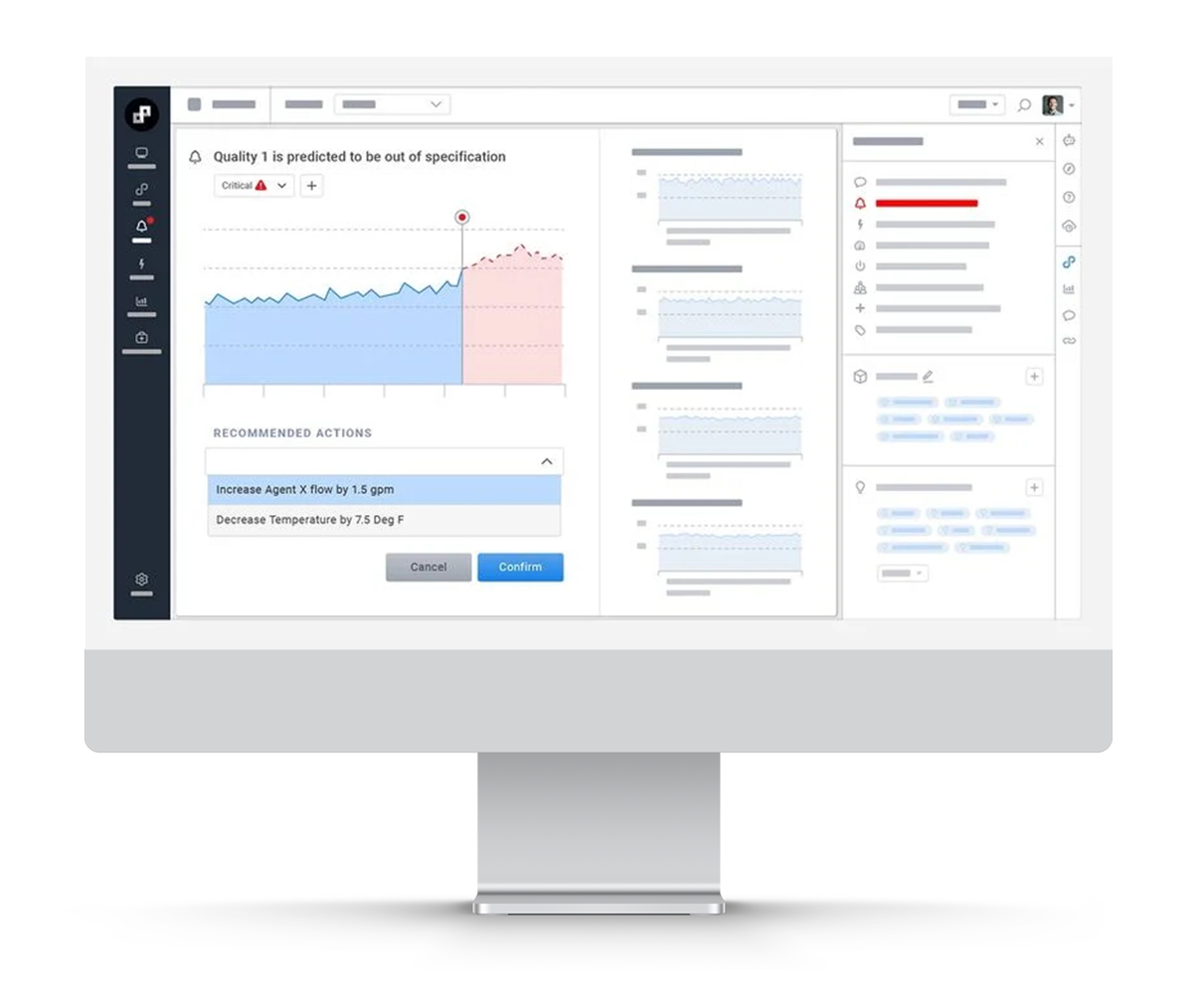

Our Quality application provides members of your production and operations team with specific, prescriptive actions they can take. Autonomous Quality, however, takes this concept one step further by establishing a bidirectional connection between TwinThread and the equipment it’s monitoring. As anomalies or inefficiencies are detected, TwinThread can drive corrective actions directly to the production process. This approach virtually eliminates the need for operator intervention and fosters an even higher degree of quality.

Accelerates Learning

- See by-line, by-product performance

- Identify best recipes/centerlines to optimize quality

- Understand top drivers for quality issues

- Prioritize automation opportunities

Drives Insights to Action

- See quality predictions in real-time

- Understand current anomalies affecting the quality

- Act on real-time recommendations to improve quality in real-time and in the future