Industrial AI That Transforms Your World

Learn how TwinThread is a partner in your digital transformation:

Webinar

Stop Optimizing Chaos: How TwinThread’s Industrial AI Platform is the Blueprint for Stability and Scalable Success

Real World Solutions. Proven Scale.

Organizations across industries are using TwinThread to innovate quickly and to transform their operations at scale.

Leading Companies Succeed with TwinThread

Discover how global leaders are applying Industrial AI, Digital Twins, and Virtual Operations Centers to drive transformational change.

Global manufacturer of premium pet nutrition applies Digital Twins and Industrial AI to drive quality to new heights

Global provider of data center design, construction, and operation services implements Virtual Operations Center across 450 sites

Global provider of environmental services enables proactive compliance management with Digital Twins and AI

Global provider of smart home products and systems launches a new digital service for residential utility optimization

Global manufacturer of engineered plastic films applies Digital Twins and Industrial AI to improve line stability and uptime

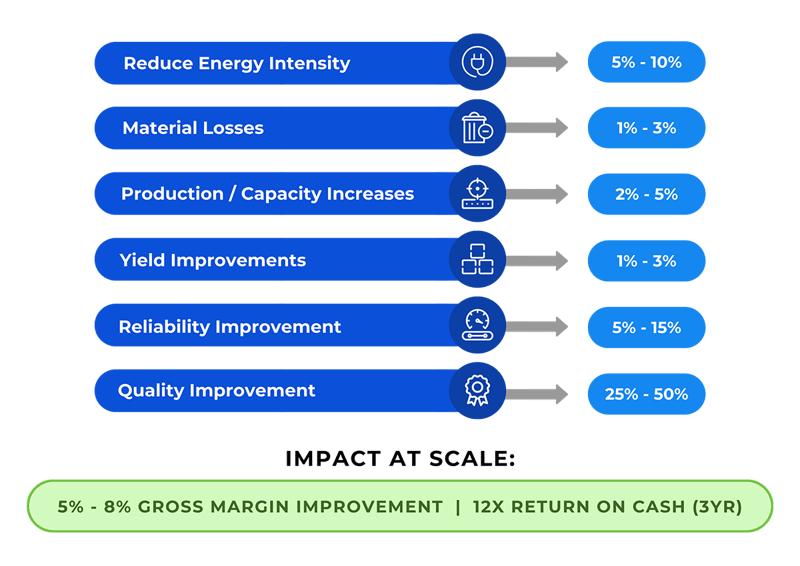

Realize 12x Returns

Pre-built solutions allow you to tackle common productivity challenges

with minimum development effort and fast time to value.

- Reduce Energy Intensity 5%-10%

- Material Losses Improvement 1% - 3%

- Production/Capacity Increases 2%-5%

- Yield Improvements 1%-3%

- Reliability Improvement 5%-15%

- Quality Improvement 25%-50%

Impact at Scale

5%-8% gross margin improvement and 12x return on cash (3yr)

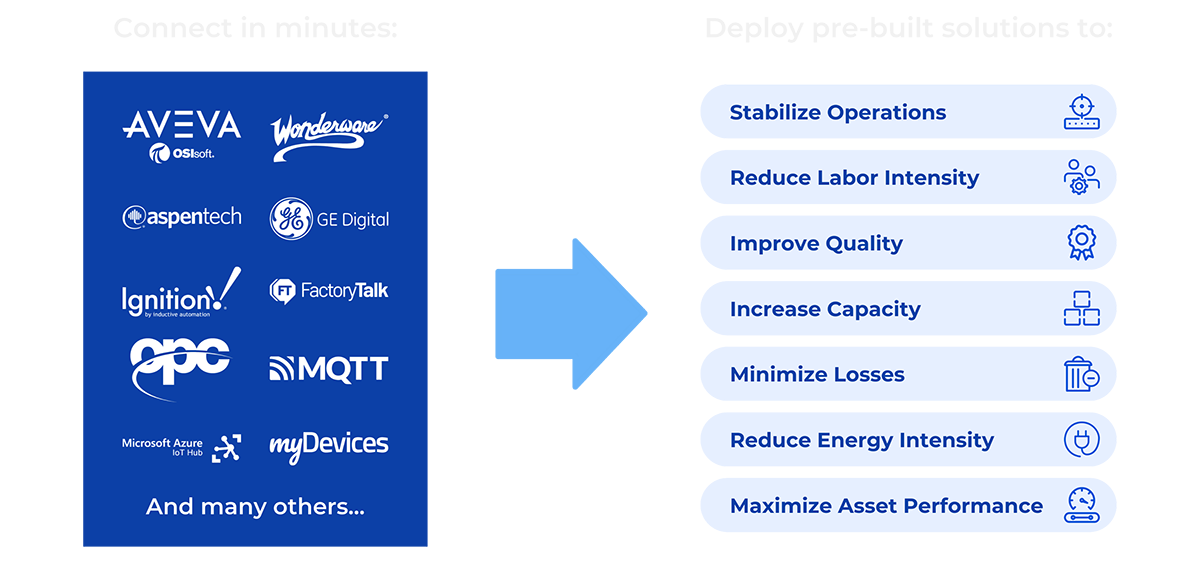

Think Big. Start Small. Move Fast.

Connect your existing data in minutes and start benefiting from Industrial AI today.

Connect Existing Data Sources in minutes:

- AVEVA

- AspenTech

- Wonderware

- GE Digital

- Ignition

- FactoryTalk

- OPC

- MQTT

- Microsoft Azure IoT Hub

- myDevices

- and many others

Deploy Pre-Built Solutions to:

- Stabilize Operations

- Reduce Labor Intensity

- Improve Quality

- Increase Capacity

- Minimize Losses

- Reduce Energy Intensity

- Maximize Asset Performance

The Secret to Scale

TwinThread’s pre-built solutions and flexible deployment architecture means that any site can start improving performance regardless of current digital maturity.

Perfect Energy

Operate at the sweet spot of production and energy consumption

Perfect Batch

Continuously evaluate batch performance and automate improvement

Perfect Quality

Reduce variability and losses and improve operational flexibility

Perfect Production

Optimize production performance across your enterprise

Perfect Centerline

Stabilize operations, start seeing consistent results, and hit your core KPIs

Uptime Optimization

Real-time alerts and recommendations to avoid downtime events

Throughput Optimization

Maximize production output on a per-product and per-asset basis

Asset Reliability

Predict and prevent common asset failure modes at scale

Asset Life

Maximize serviceable life and proactively manage failure risks at scale

TwinThread Differentiators

Rapid Time to Value

Prove return on investment quickly with pre-built solutions and minimal development effort.

Operationalize

Enable fully autonomous actions with powerful workflow and open integration capabilities.

Innovation

Experts can innovate quickly by applying Industrial AI with built-in no-code development tools.

Scalability

Demonstrated track record from single sites to hundreds of sites involving millions of sensors.

Innovate Now

TwinThread’s Industrial Cloud Platform offers you many opportunities to innovate by embracing and extending the automation systems you have in place today.

Virtual Operations Center

Monitor, manage, and coordinate operations across various locations and systems.

Operationalization

Encourage real change by

translating Industrial Data into

automated improvement actions.

Digital Twins

Virtualize your assets and production

processes to enable the next generation

of automation and autonomous operation

capabilities.

AI Modeling

Leverage our pre-built and customizable solutions to deliver automated prescriptive recommendations that improve your operations fast.

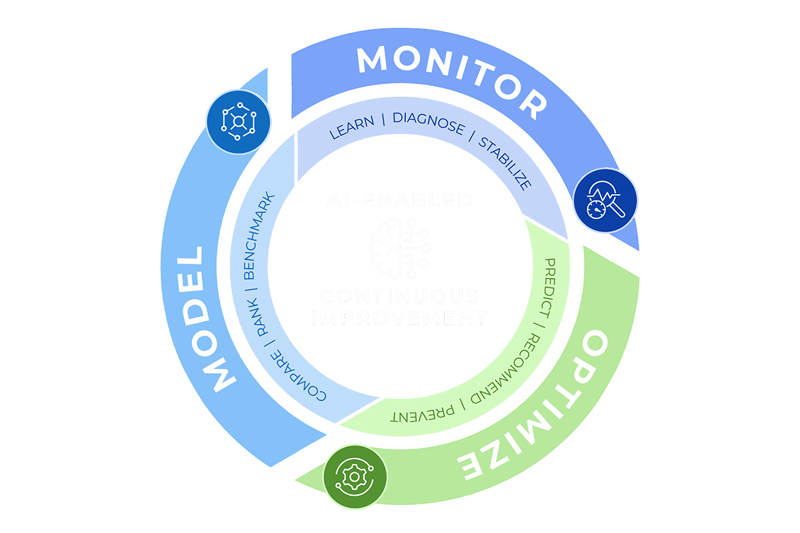

AI-Enabled Continuous Improvement

- Model:

- Compare

- Rank

- Benchmark

- Monitor:

- Learn

- Diagnose

- Stabilize

- Optimize:

- Predict

- Recommend

- Prevent

Revolutionize Continuous Improvement

Industrial AI and Digital Twins transform how Continuous Improvement works.

Identifying, prioritizing, and executing improvement initiatives has never been more automated and efficient.

Want to learn more about Industrial AI?

Stay Connected with Industrial AI Trends and Platform Features

Get quarterly updates from our experts. Stay ahead with insights and strategies for digital transformation and operational excellence.